In Southern Italy, for over forty years, Campa Sistemi has been combining craftsmanship with exceptional quality. Our winning formula? Passion and innovation—what keep us at the forefront of a dynamic market, delivering fully customized solutions.

Our mission is clear: to unite artisanal expertise with the highest quality standards, offering the best solutions for both private homes and professional spaces.

At Campa Sistemi, we believe every client is unique, and every window or door should reflect the personality and needs of the person who chooses it. That’s why, before we begin any project, we carry out a detailed site inspection at your home or workplace. This allows us to fully understand the environmental, aesthetic, and functional requirements—ensuring every detail is thoughtfully considered.

Following the site visit, we provide personalized consultation. Our team of experts is at your complete disposal to advise you on design, materials, and the most suitable technical solutions for your space. We listen closely to your ideas and needs, and together we define the perfect solution.

Finally, we bring your custom-made fixture to life. Each piece is one of a kind, crafted specifically to reflect your vision and the unique characteristics of your space. Our experience and passion are embedded in every detail, delivering a high-quality product that’s functional, durable, and beautifully made.

With Campa Sistemi, every fixture tells a story—yours.

Every Campa Sistemi fixture tells a story of dedication.

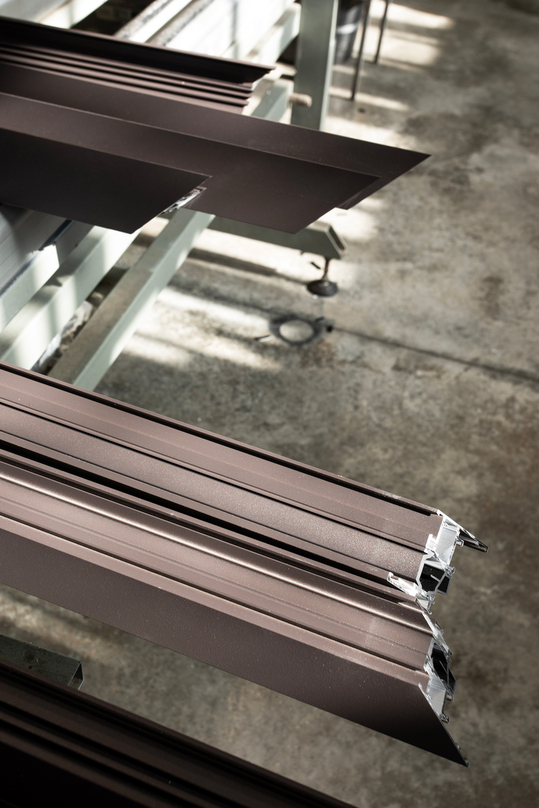

We select only the finest metals to craft custom-made doors and windows. For us, quality isn’t just about the final product—it’s a journey that begins with the careful selection of raw materials and culminates in the skilled hands of our artisans. This is our philosophy.

HOW WE CRAFT OUR FIXTURES

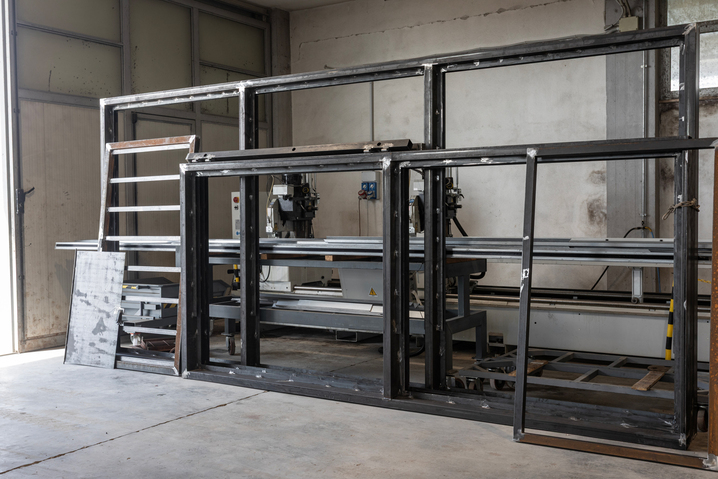

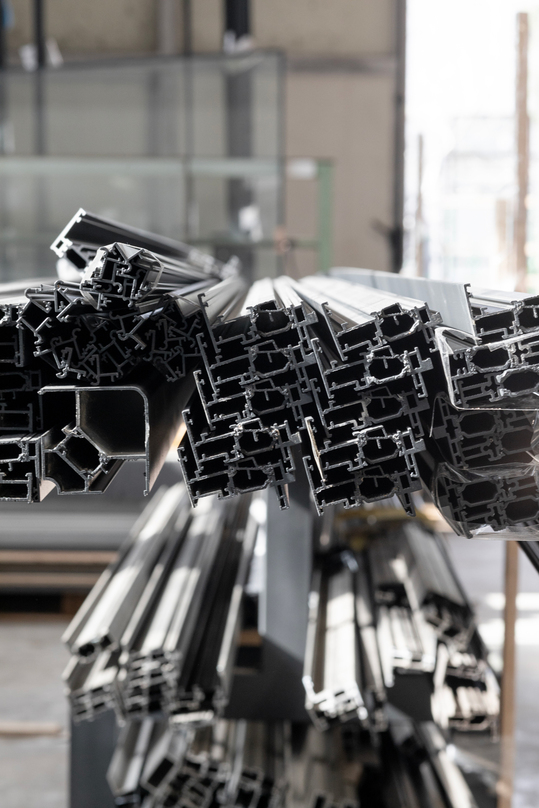

Our production process relies on the expertise of master craftsmen, with minimal automation. Once the materials are received and thoroughly inspected, they are carefully handled and organized throughout our warehouse.

The first steps involve a strict quality control process. Materials like steel and aluminum are readily available, ensuring both efficiency and premium standards. The cutting and profile-processing phase is all about precision—every cut, every hole, every detail is executed with care.

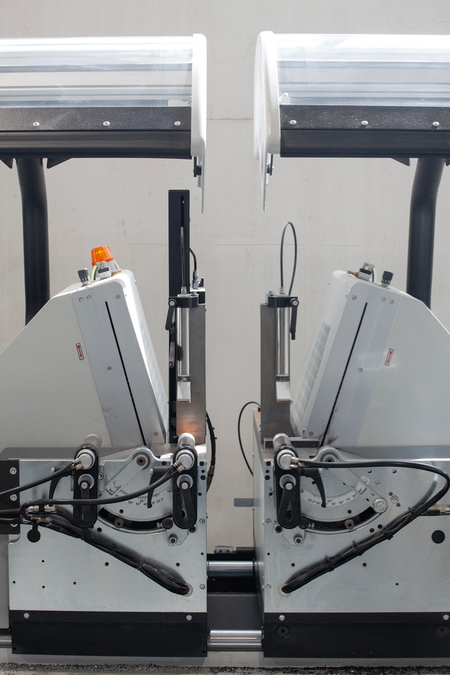

In the ever-evolving world of window and door systems, precision and efficiency are at the core of every project. With the aid of CNC machines for cutting and drilling, we’ve taken our production standards to the next level.

One of the most impressive features of CNC machines is their millimetric precision.

When it comes to doors and windows, a precise cut or drill can mean the difference between a high-quality product and a mediocre one.

Beyond precision, CNC machines are remarkably fast. This allows us to produce large volumes of fixtures in shorter timeframes, meeting customer demands with quick turnaround times.

CNC machines are fully programmable, meaning they can be adapted to execute a wide range of designs and patterns. This versatility enables us to offer truly customized solutions, delivering fixtures tailored to each client’s specific requirements.

A key step in the process is welding—where art meets technique to bring the fixture to life.

Robotic painting ensures both aesthetics and protection, while metal burnishing enhances the natural beauty of the materials we use. And it doesn’t stop there: each fixture is carefully assembled and securely packaged to ensure it arrives in perfect condition.

EVOLUTION & QUALITY: THE SUCCESS OF CAMPA SISTEMI FIXTURES

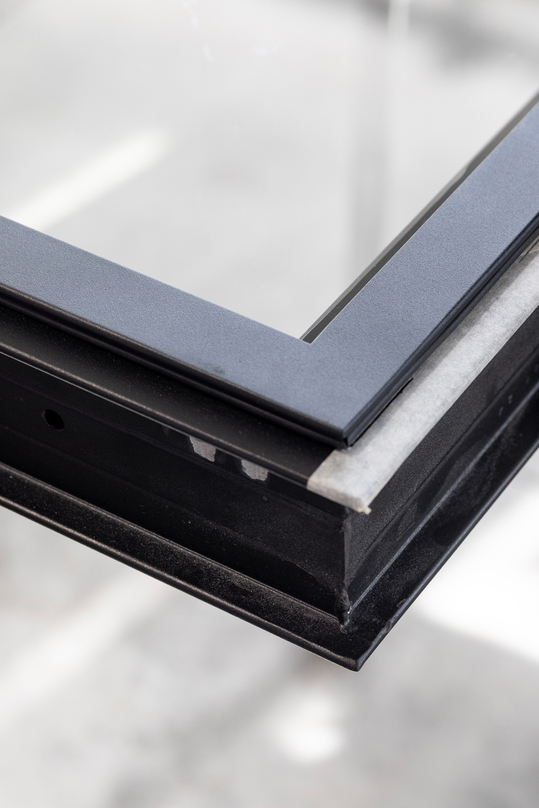

Over the years, steel fixtures have undergone a remarkable transformation. A cornerstone of this evolution is the thermal break profile—Campa Sistemi’s flagship feature in all its creations. Introduced in 1990, this innovation propelled thermal performance to new heights while maintaining a refined, minimalist aesthetic.

THE MECHANICS OF THERMAL BREAK

Crafted using metal profiles, our thermal break fixtures combine two sections—either steel or brass—joined by a dense polyurethane resin reinforced with a central polyamide core. This unique connection strengthens both metal components, providing exceptional thermal insulation and optimal structural resistance.

AT THE FOREFRONT OF INNOVATION

With a catalog of over 200 different profiles and a wide variety of finishes, we have masterfully fused artisanal craftsmanship with cutting-edge technology, establishing ourselves as a leading name in premium fixtures.

The growing demand for large glass surfaces has emphasized the importance of precisely engineered structural reinforcements. That’s why we don’t just design—we manufacture our reinforcements with the same dedication and precision.

BUILT TO LAST

What truly defines the quality of our fixtures is their durability. Our team of experts works tirelessly to deliver products that not only meet but enhance the specifications of every project—ensuring comfort, safety, and peace of mind for today and tomorrow.

DETAILS THAT MAKE A DIFFERENCE

At Campa Sistemi, security is at the heart of every design. All our fixtures come standard with multi-point locking systems—a true hallmark of safety. Additionally, we use heavy-duty, adjustable hinges to ensure long-lasting performance and smooth operation. Our gaskets are engineered to withstand the harshest weather conditions.

We collaborate with independent testing laboratories to ensure each product meets the highest standards, even under extreme conditions. This commitment is backed by the Miami-Dade Florida Impact Rating certification, a testament to the outstanding quality and performance of our fixtures. At Campa Sistemi, we go beyond aesthetics—we deliver unmatched strength and functionality.